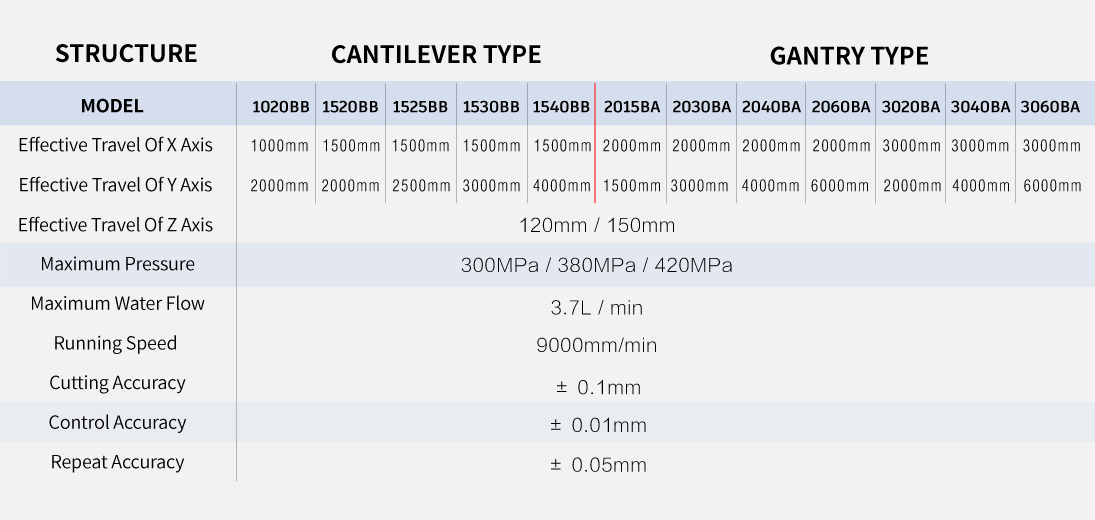

Intelligent Software Compatibility

The software has a built-in rotation axis control module , which does not require borrowing data from other transmission axis. Whether cutting plates or pipes, you can start without switching data, which is convenient and fast.

Full Servo CNC Drive

The pipe turning mechanism adopts CNC servo motor drive, which can meet the cutting of any shape and curve of the pipe surface. Whether cutting sheets or pipes, the error is within a millimeter, and the accuracy is precise.

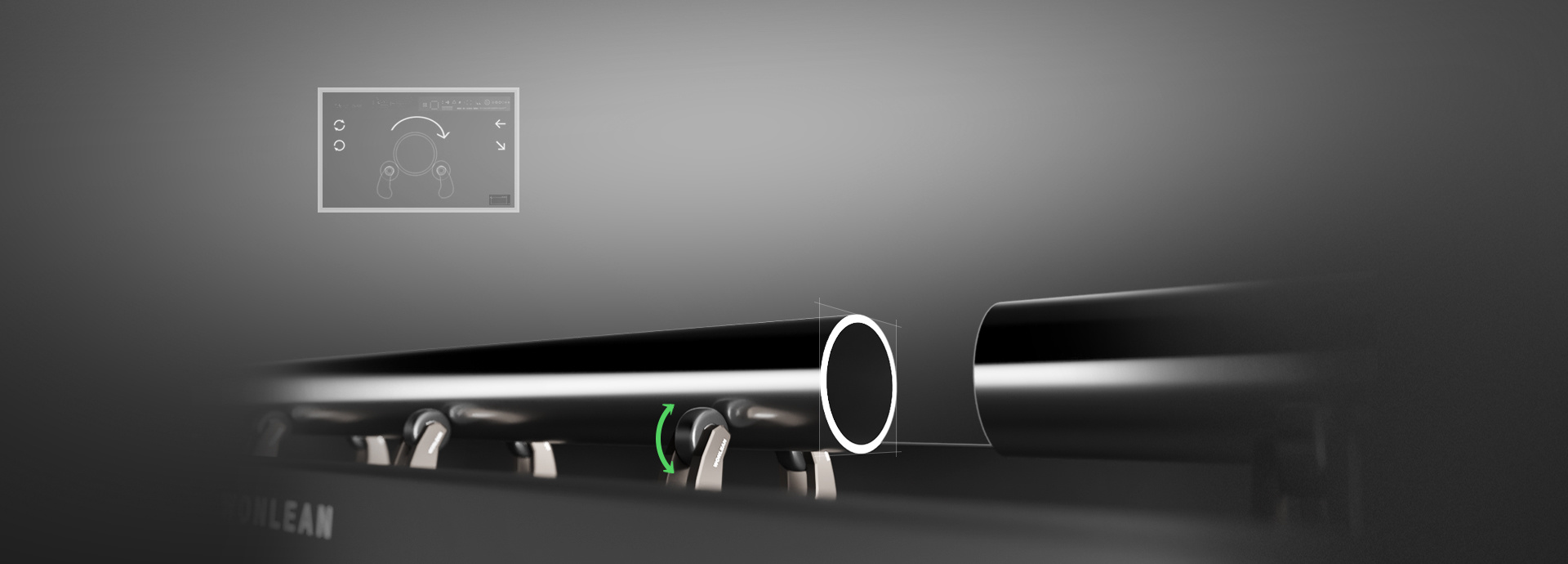

Concrete Casting Bed

After finite element analysis, the bed is welded with the best stress points and support structures. After aging treatment, the bed is cast with concrete , providing extreme stability and excellent shock absorption. This greatly reduces bed stress and maintains accuracy in the long term.

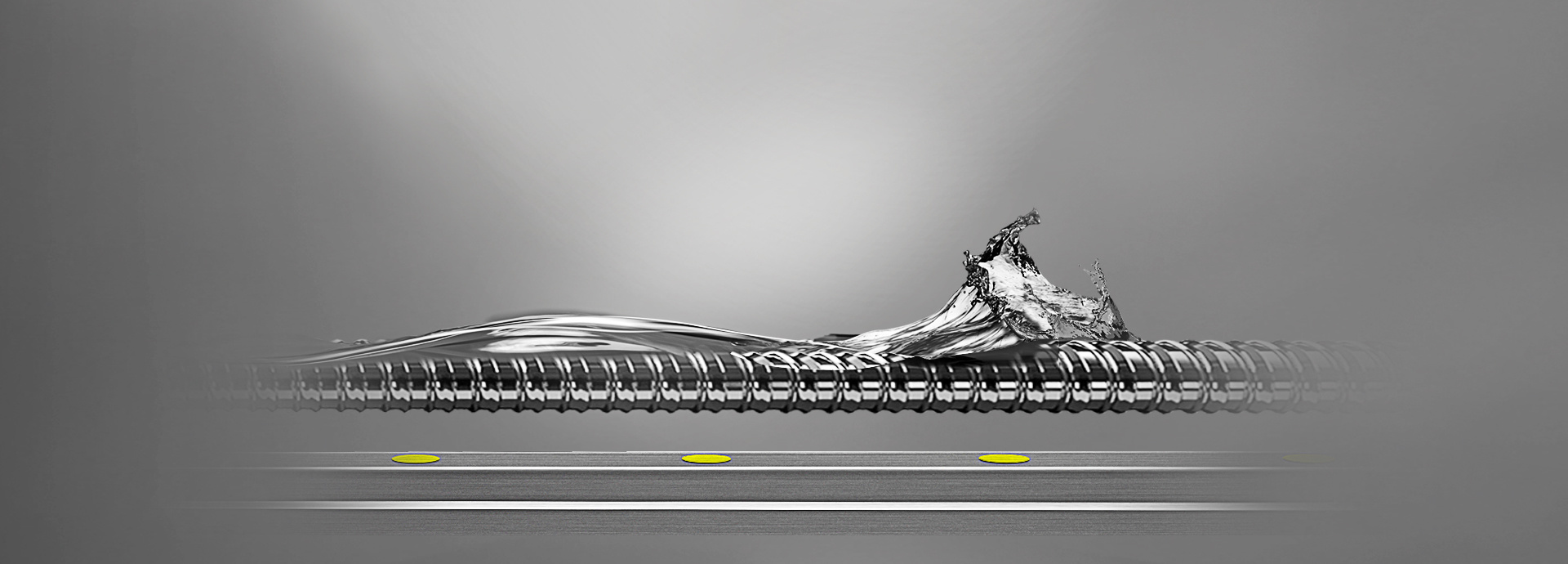

Oil-Immersed Structure

The guide rail and ball screw are fully immersed in an oil tank,providing ample lubrication and preventing the wear of the transmission system caused by abrasive and water splash. This feature not only provides ultra-high cutting precision but also greatly improves the lifespan of the machine, solving the issue of serious accuracy degradation in traditional water jet cutter. And no matter when the cutting is accurate.

Split Structure

The bed and water tank of the waterjet cutting table are completely separated, adopting split design that avoids the risk of the bed becoming deformed due to the deformation of the water tank over time and ensures the precision and lifespan of the bed.

Customized Design

We can customize the waterjet cutting table according to the size of your workpiece, and only the most suitable one is the best.

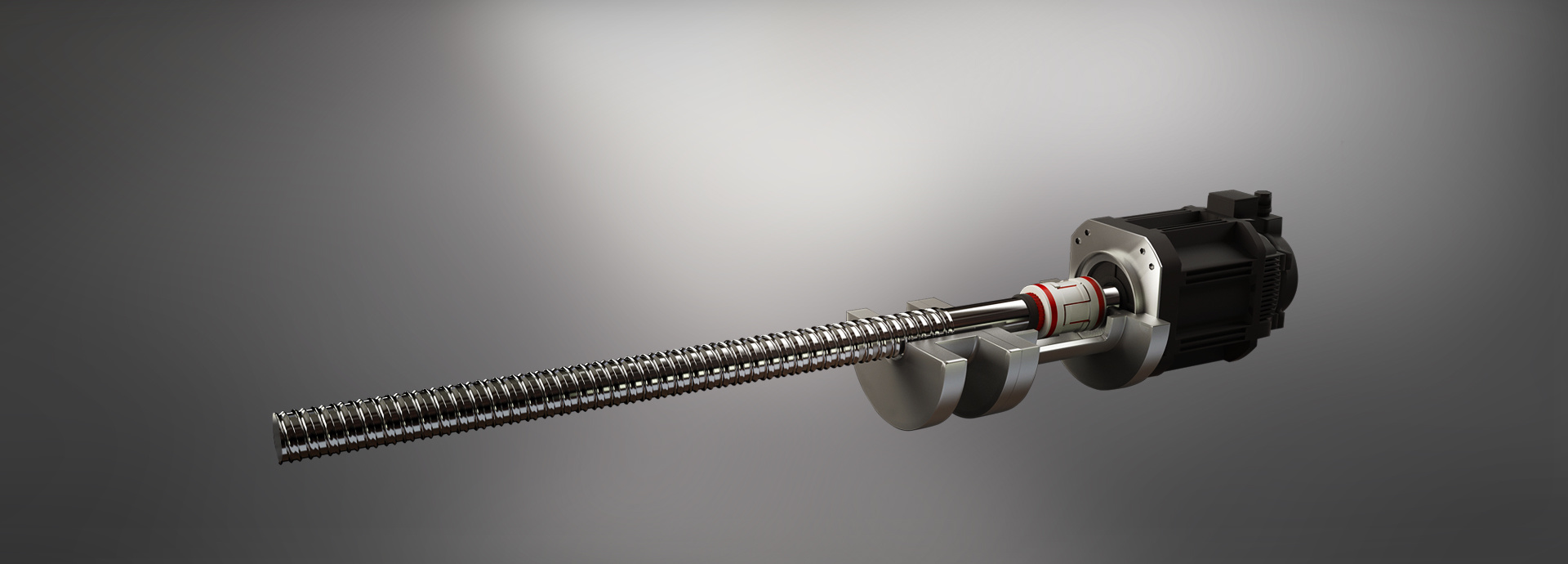

Direct Connection Transmission System

The high-power servo motor is directly connected with large-diameter ball screw and guide rail, which has smaller transmission losses, higher precision, and greater stability compared to traditional synchronous belt connection. The accuracy is achieved to within a thousandth of a millimeter.

Stainless Steel Double Sealing

The X, Y, Z axis adopts an external high-quality stainless steel wire drawing casing and internal high-quality dustproof folding design, providing double-seal protection that effectively protects the machine and ensures complete sealing. This is currently the most effective sealing form for waterjet cutter.

Intelligent Variable Boosting System

Equipped with a variable oil pump and a intelligent variable high pressure system consisting of four imported valve bodies, our intelligent variable pressure system intelligently adjusts the oil volume based on pressure requirements, ensuring high cutting efficiency, better oil temperature control and more energy-saving.

Intelligent identification one-click processing

Automatically identifies CAD electronic drawings and generates cutting path and access parameters, reducing manual coding and repetitive operations while simplifying operations and improving productivity.

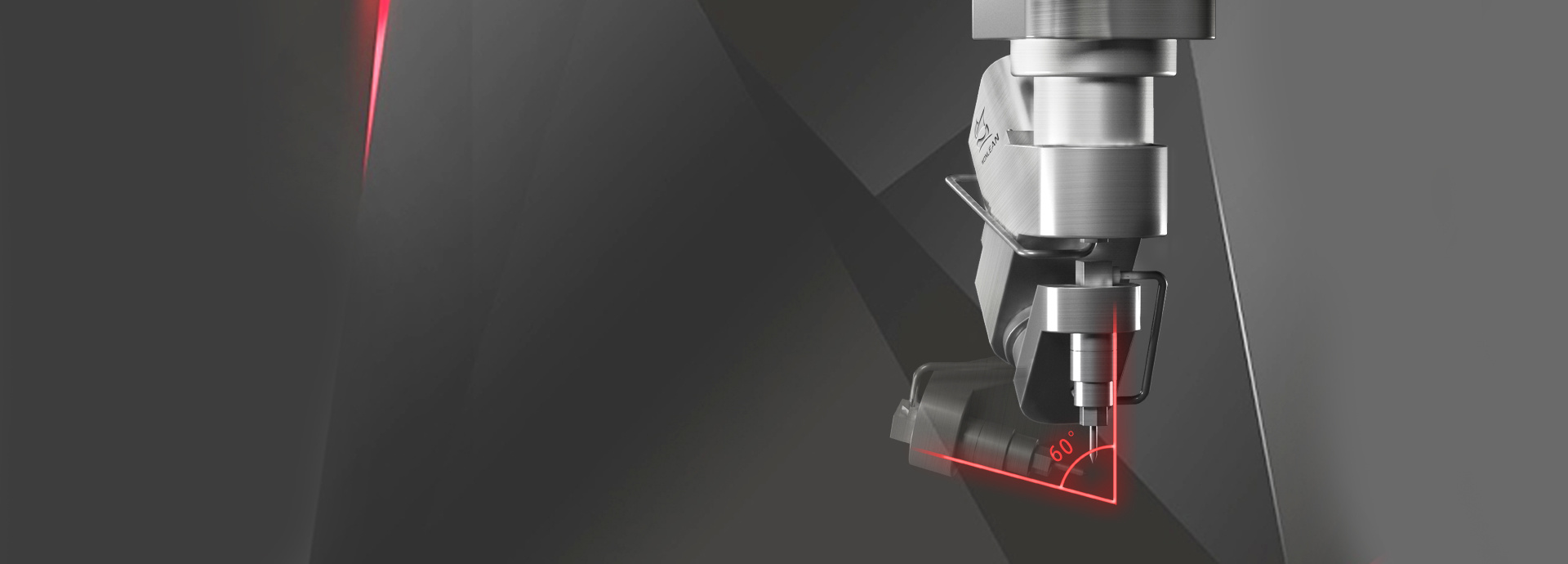

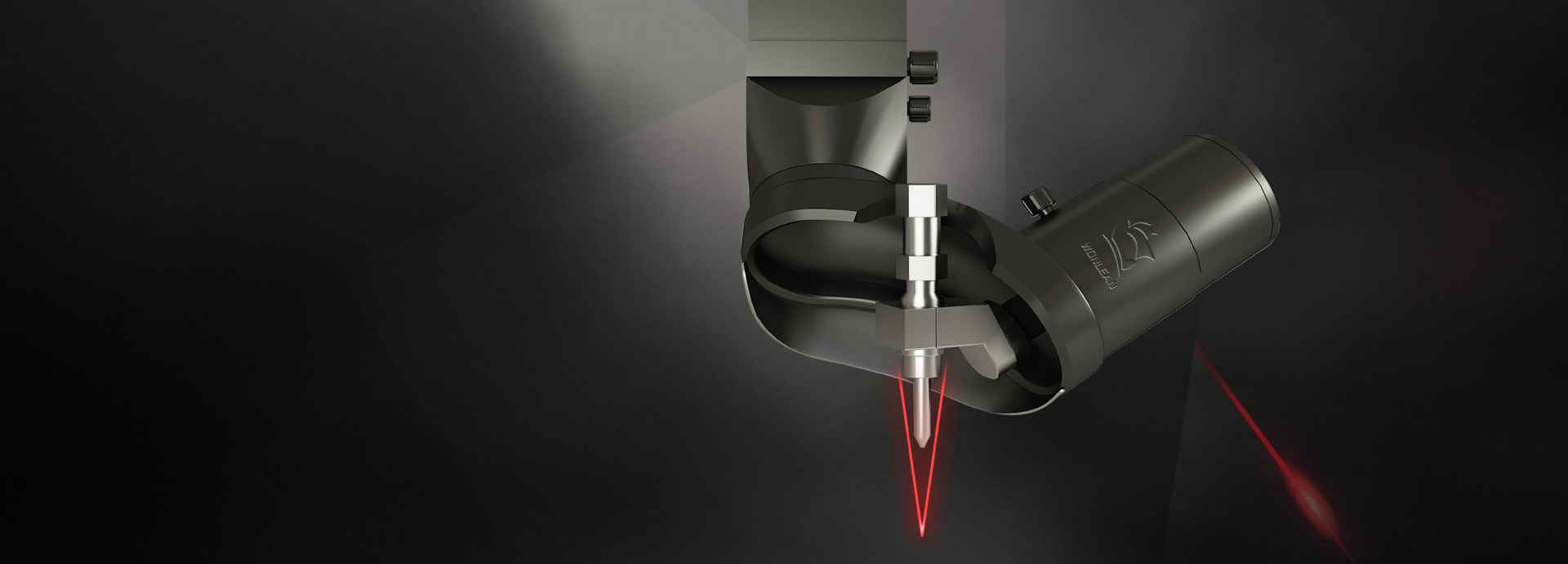

Intelligent 3D Waterjet Cutting

Enables fixed and variable angle cutting of up to 60 degrees, with an aluminum alloy cutting head structure that is lightweight, high strength, and has a small load. The cutting position deviation under 380Mpa high-pressure water is less than 0.01mm ,and the cutting accuracy is extremely high.

Tilting Compensation System

Utilizes intelligent five-axis software and two Japanese Yaskawa servo motors for dynamic compensation, achieving precise active compensation for the "V" -shaped incision of the water jet cutter and vertical cutting or bevel cutting within 10 degrees.

Wireless Remote Control Handle

Everything is under control

Flexible and convenient for tool adjustment

All functions from one

Control machine operation at any time

Magnetic suction design for easy access

The Main Components Adopt Internationally Renowned Brands

International top quality accomplishes the Wonlean classic