Cage-type Bed

Wonlean Cage-type bed adopts integrated framework structure. The design incorporating water tank space into unify make structure more hard and stable. This design also increase 35% capacity, saving covering area, besides, modular assembly decreases 40% installation procession, ensuring equipment stable operation in long term.

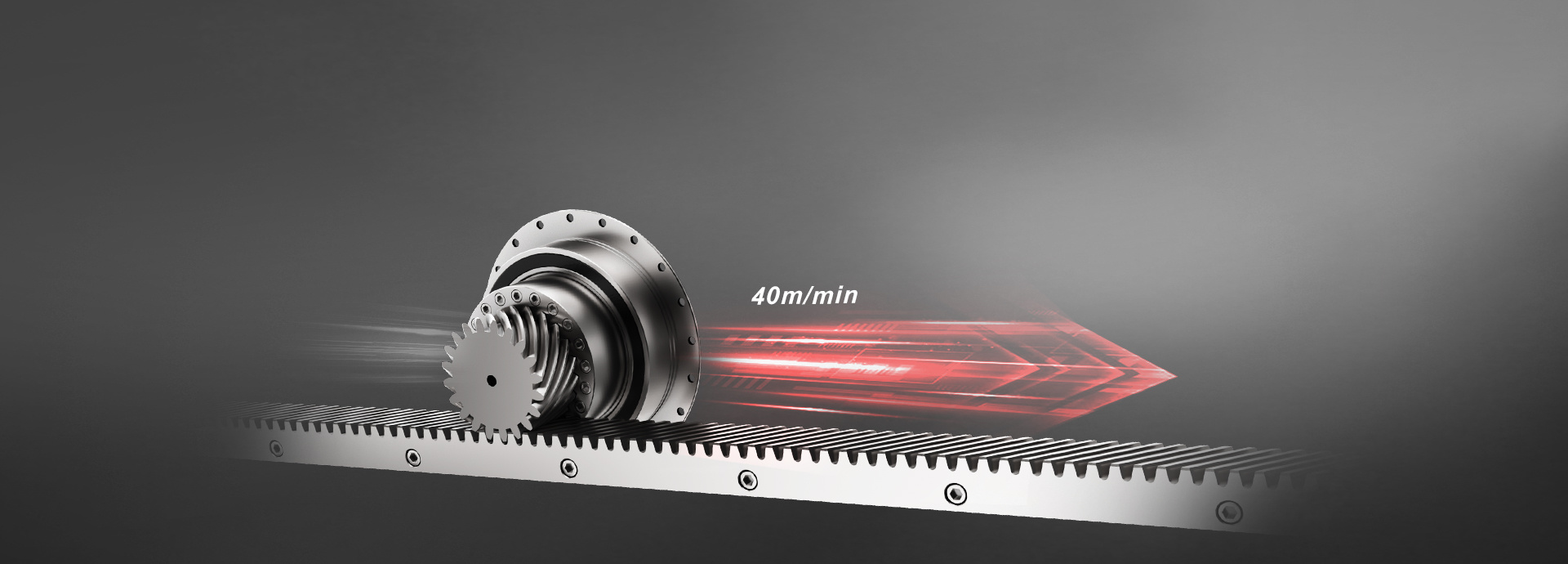

High-efficiency and Lossless Transmission

Wonlean innovative Nanoscale grinding rack and pinion system solves the problem of power transmission loss in industrial equipment. Compared to traditional water jet cutting machine that utilize thin ball screws for transmission, which are susceptible to vibration and overheating, this system ensures stable high-speed operation at 40m/min through precision tooth flank mesh, with no power loss in long travel distances. It is proved that it can increased 20%-60% production efficiency.

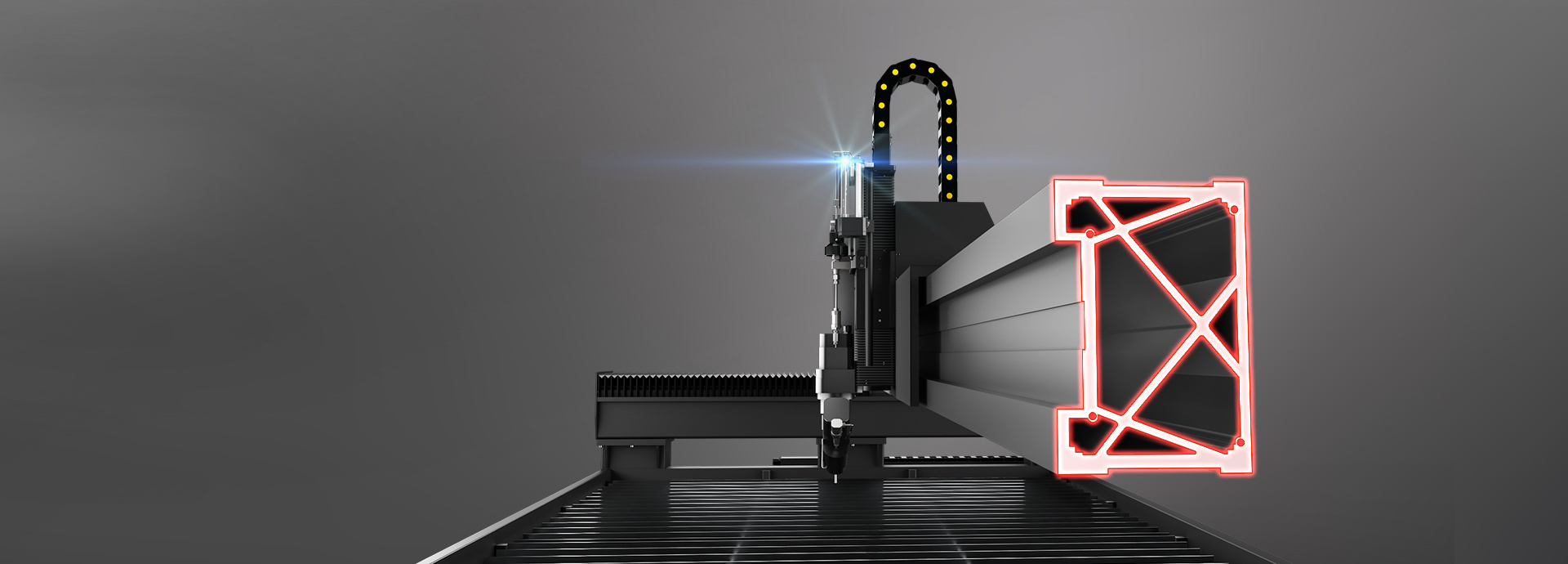

Balance Strength and Lightness

Wonlean adopts high-density aircraft-grade aluminum crossbeam( density 2.7g/cm3 ), promoting 20% strength with the weight decreasing 30%. High-pressure stretching technology promotes dynamic performance 20%. Precise control and stress relieving technology suppresses vibration. After test, this design makes key parts life over 30,000 hours.

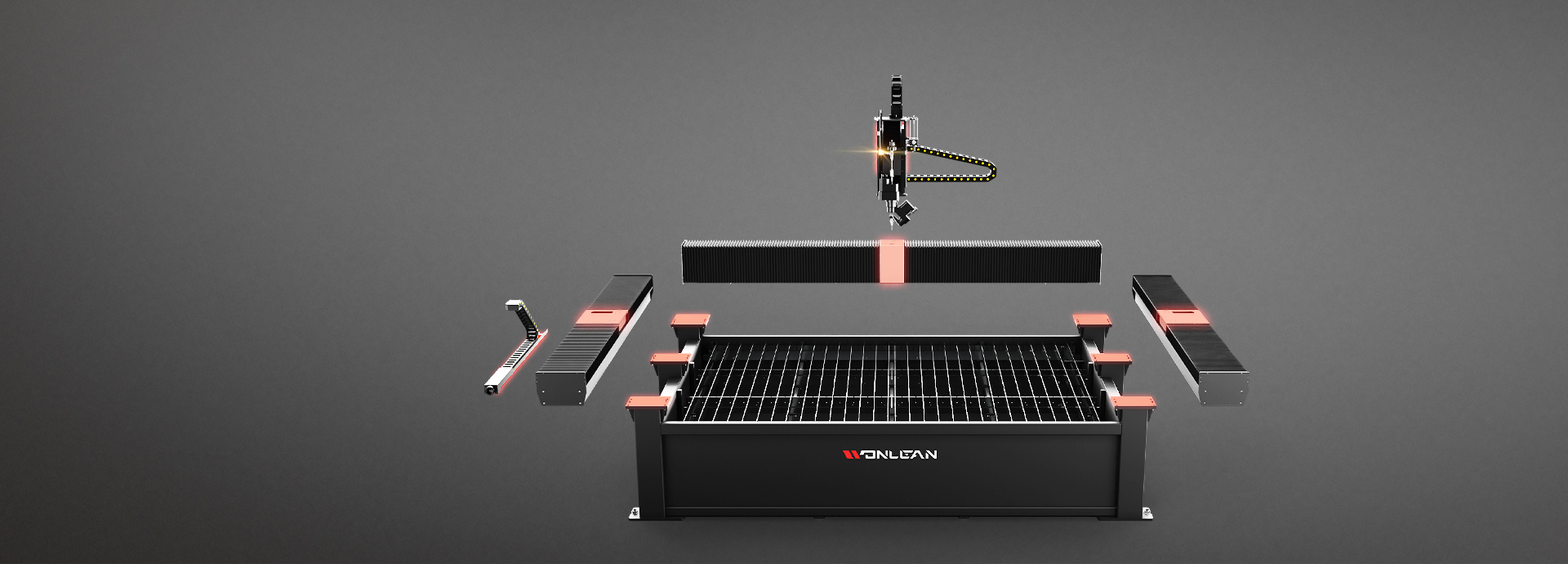

Modular Design

Wonlean modular design is highly flexible, which can equip freely to match various requirement perfectly. From small scale precision machining to large scale mass production, we all offer customized solutions, contributing to enterprises developing efficiently.

High-Quality Dustproof Folding Cloth

The X, Y, Z axis adopts a fully sealed design with high-quality dustproof folding cloth, capable of folding up to 100000 times, ensuring durability.

Adaptive Voltage Regulation System

It has a pressure adaptive balancing device that can greatly alleviate pressure pulse fluctuations to improve cutting efficiency and reduce the impact of pressure pulses on the cooling system.

Intelligent identification one-click processing

Automatically identifies CAD electronic drawings and generates cutting path and access parameters, reducing manual coding and repetitive operations while simplifying operations and improving productivity.

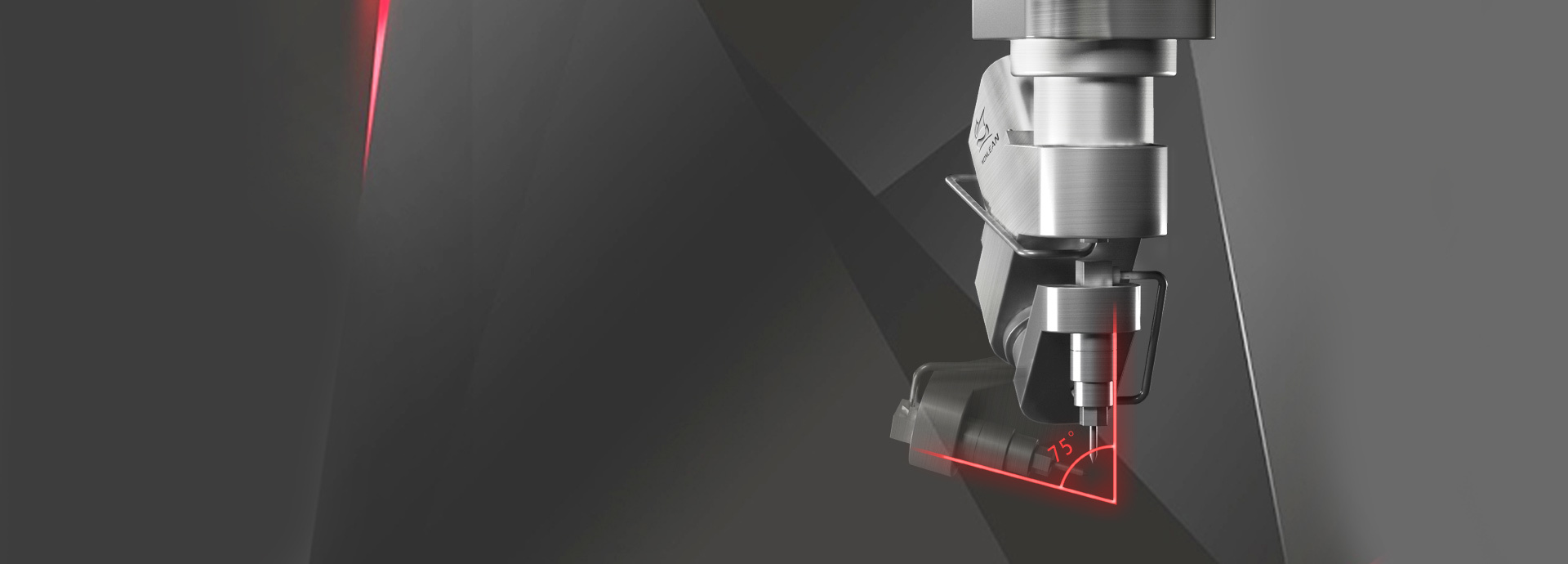

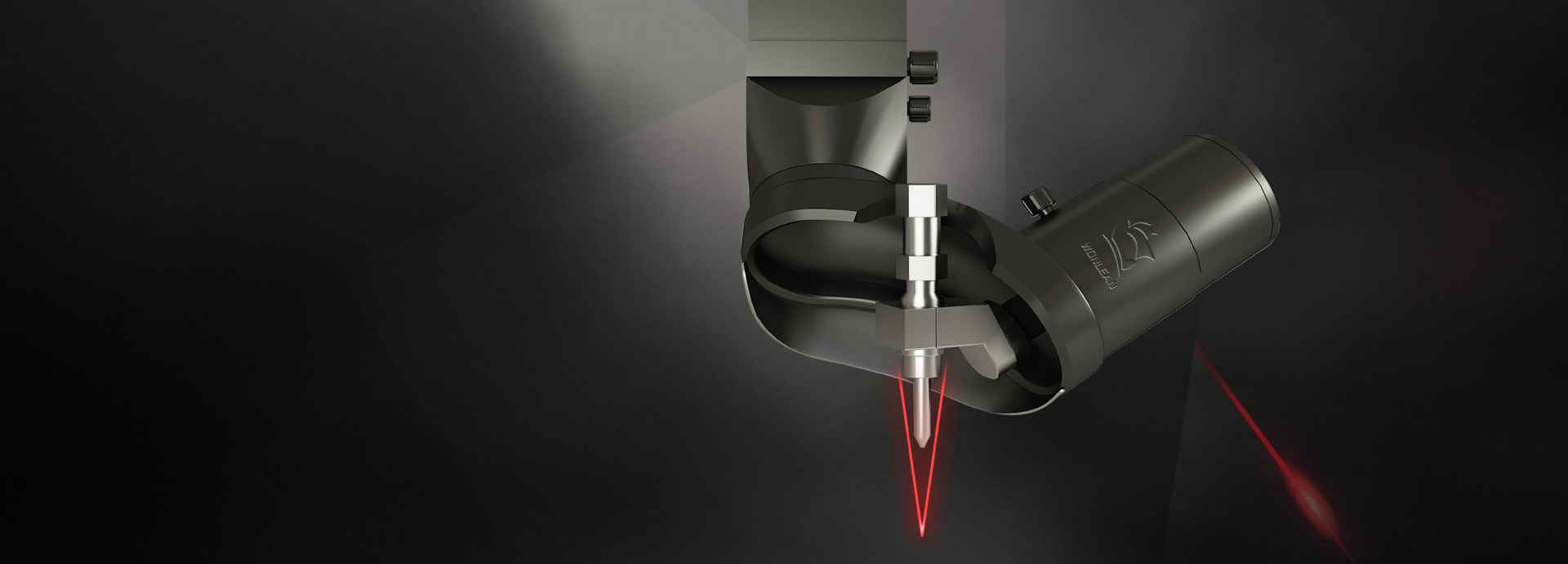

Intelligent 3D Waterjet Cutting

Enables fixed and variable angle cutting of up to 60 degrees, with an aluminum alloy cutting head structure that is lightweight, high strength, and has a small load. The cutting position deviation under 380Mpa high-pressure water is less than 0.01mm ,and the cutting accuracy is extremely high.

Tilting Compensation System

Utilizes intelligent five-axis software and two Japanese Yaskawa servo motors for dynamic compensation, achieving precise active compensation for the "V" -shaped incision of the water jet cutter and vertical cutting or bevel cutting within 10 degrees.

Whether it’s metal, glass, stone, or composites, our Water Jet Cutting Machine effortlessly handles a wide range of materials.

The Main Components Adopt Internationally Renowned Brands

International top quality accomplishes the Wonlean classic